The structural repair of the cantilever edges, both on balconies and on the façade, is the type of repair of the surface reinforcement in the edge of reinforced concrete elements exposed to the elements. It can be beams, straps, floor slabs.

When performing an inspection or when we are commissioned an project of rehabilitation of facade it is common to find slab edges or balconies with cracks and / or breaks. These injuries are frequent in old buildings in which the facade only has a plaster coating or even a layer of paint on the concrete.

As the concrete is exposed to the elements, the environmental aggressiveness penetrates easily until it reaches the reinforcement of the balconies, causing it to rust and to produce breaks and cracks in the slabs. These cracks are visible to the naked eye, although in many cases the communities of owners do not act as soon as they detect the cracks, causing a problem with a quick and inexpensive solution to become a problem with a more complex and expensive solution.

In case you find cracks or breaks in the facade of your building It is necessary that you contact a qualified technician, these cracks in most cases are not very important, but they should be studied. Sometimes they require an accurate diagnosis that establishes the causes and attacks the origin of the problem, not the symptom. This makes it possible to eliminate the problem effectively and not simply by hiding it behind a layer of mortar and paint.

Next, we explain how to carry out a rehabilitation on the edges of the balconies in an effective way, completely eliminating the root of the problem.

STEP ONE: DETECT THE EXTENT OF THE INJURY

When cracks are detected in the floors, it is possible that the oxidation of the reinforcement is not only occurring under the cracks but also in other areas where no breakage has yet occurred and therefore cannot be detected with the naked eye. .

There are various methods to check the extent of the injuries caused by oxidation, tastings or tests using thermographic imaging are the most effective and allow a detailed injury plan to be carried out.

In case the community prefers not to carry out any of the above methods, the technician must carry out a detailed visual inspection, checking all the balconies. This method requires leaving a large margin of surface area to be repaired in the measurements of the rehabilitation project so as not to fall short and include check items, in the long run it tends to slow down and make the rehabilitation more expensive.

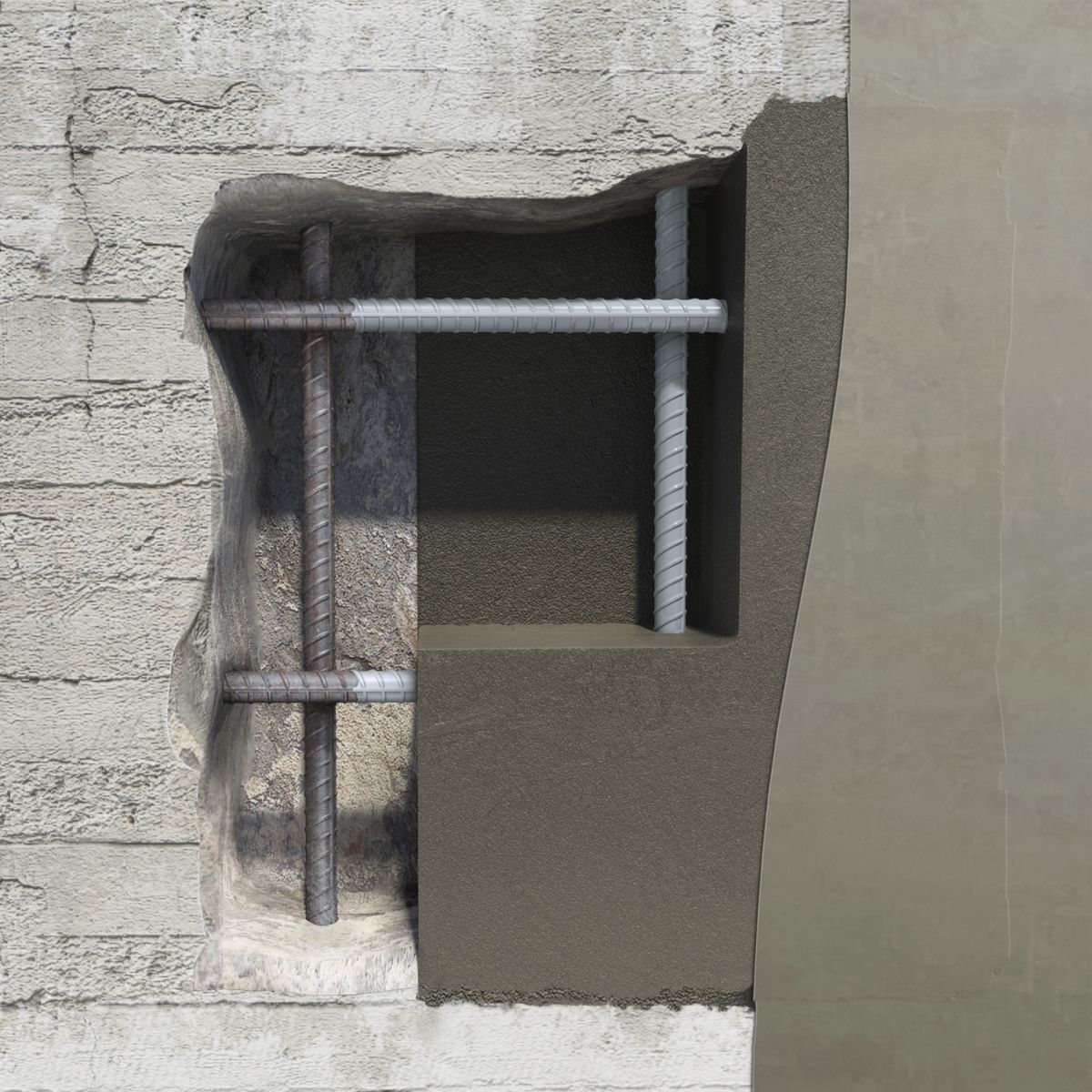

STEP TWO: CHOP THE CONCRETE AND REMOVE THE RUST FROM THE REINFORCEMENT

Once the affected areas have been determined, the layer of damaged concrete must be minced until it reaches the reinforcement bars. During this step it is important to ensure that the steel bars have been “out” of the concrete and that a minimum gap of 2cm has been left to be able to completely remove the rust.

Once the concrete has been chopped, it is convenient, if the building is from the years 1950 to 1980, send samples of the material to be analyzed to know if our building has cement aluminous . Although it has not caused problems in other places, it is good to know if our building has aluminous concrete for future prevention.

With all the affected steel exposed, the oxide layer is removed by scraping the steel systems, the most common being brushing the bars with metal brushes around the perimeter. After brushing, the treated surface must be cleaned to remove the remains of concrete dust or rust, otherwise the reconstruction of the concrete may be difficult and the rust particles may reproduce.

STEP THREE: PROTECTION OF THE REINFORCEMENT AND RECONSTRUCTION OF THE CONCRETE

With the oxide completely removed from the armor, we proceed to apply products and antioxidant treatments to prevent the repair of the oxide. The application of these products must be carried out in the shortest time possible after cleaning the rust, since having the steel fully exposed to the elements, the risk of oxidation is high.

The oxidation of the steel makes it increase by 10 times its initial size. So if we see that there is half a centimeter of rust, 5 mm, that means that we have structurally lost 0.5 mm of armor.

Safety is not normally compromised by slight oxidation, although it is cumbersome. Despite this, it must be taken into account that in specific cases a large part of the steel may almost have disappeared. In these cases, you must proceed to perform reinforcements to solve it.

After protecting the steel, the crushed concrete is restored, with the application of cementitious mortar with a high PH to provide additional protection to the internal reinforcement. It is to choose the mortar that has the least possible shrinkage, apart from a high structural resistance , to avoid the appearance of cracks or fissures in the old concrete and to control the porosity after hardening.

STEP FOUR: FINISH COAT APPLICATION

In case the reconstruction of the concrete has been carried out with high PH mortar, the finishing layer is treated as an aesthetic element rather than as a protection to the concrete. But if you want you can apply a finishing monolayer mortar so that it remains the same as the rest of the facade, it would be convenient to previously apply a layer of bonding bridge.

It is also appropriate, although this would be for an excellent note, thermally insulate with a sate system the structure (isolated structures always last longer as they are not exposed to so many fluctuations in ambient temperature)

Leave A Comment